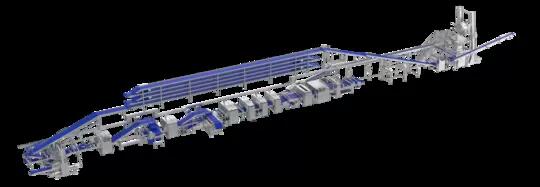

ASTec industrial lines

RONDO ASTec industrial lines are designed to meet the most stringent hygiene criteria. In 24-hour operation, they uniquely combine gentle processing of dough with the utmost precision. And they are compatible with both upstream and downstream installations.

Strengths

The strengths of the RONDO ASTec lines

Reliable and hygienic

- ASTec meets the highest hygiene standards

- Easy servicing and quick cleaning

- High-quality materials and components

- 2 variants available: ASTec D for dry cleaning and ASTec W for wet cleaning

User-friendly thanks to RONDO Control Concept

- Intuitive operation with large symbols

- All relevant data displayed concisely on one screen

- Automatic log, including cleaning (for audits)

- Greater productivity and fewer errors thanks to simple operation

Better dough – better baked goods

- MIDOS ensures gentle dough processing

- Guaranteed homogeneous, identical dough pieces

- Also suitable for highly hydrated doughs with long resting times