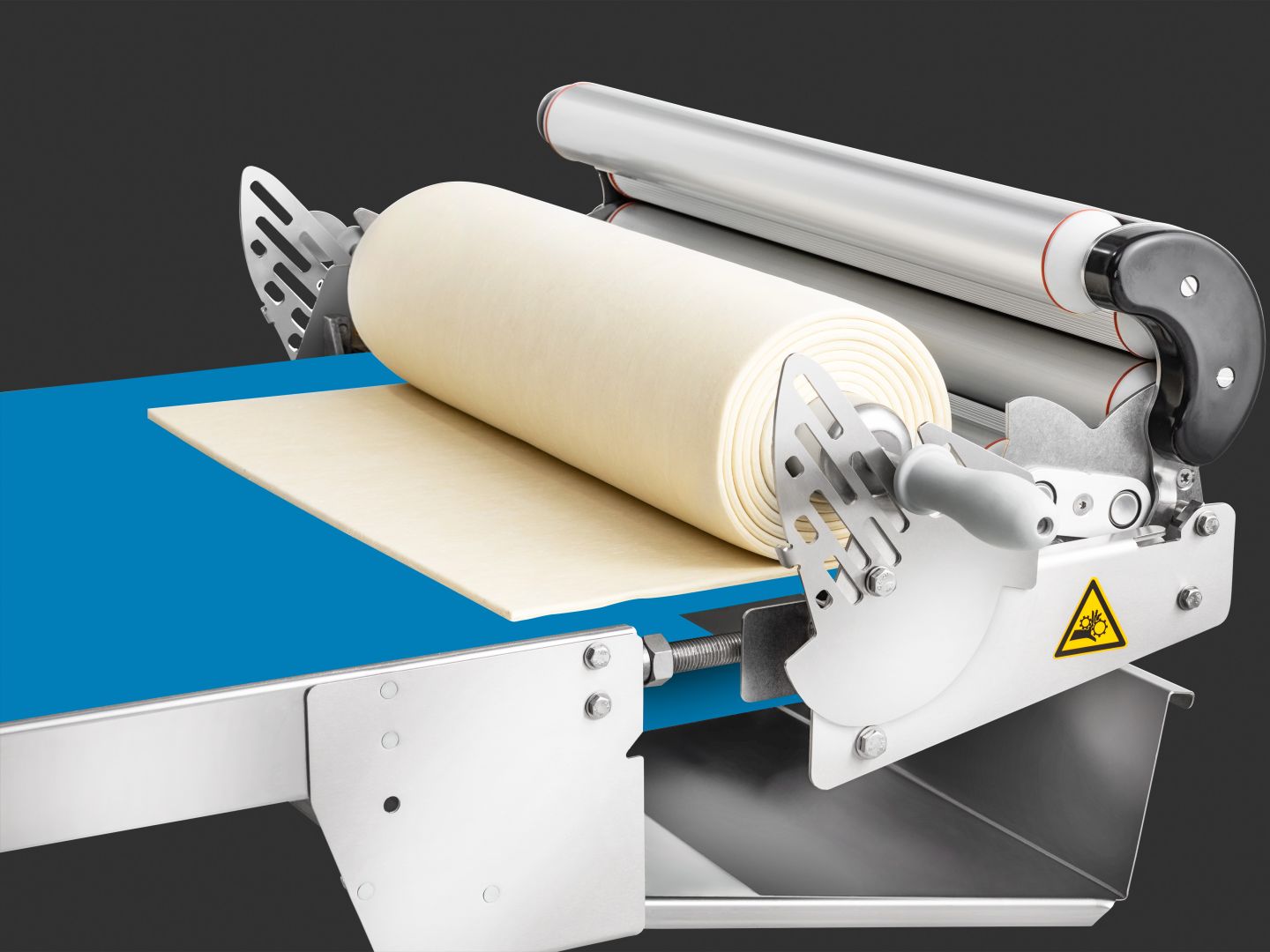

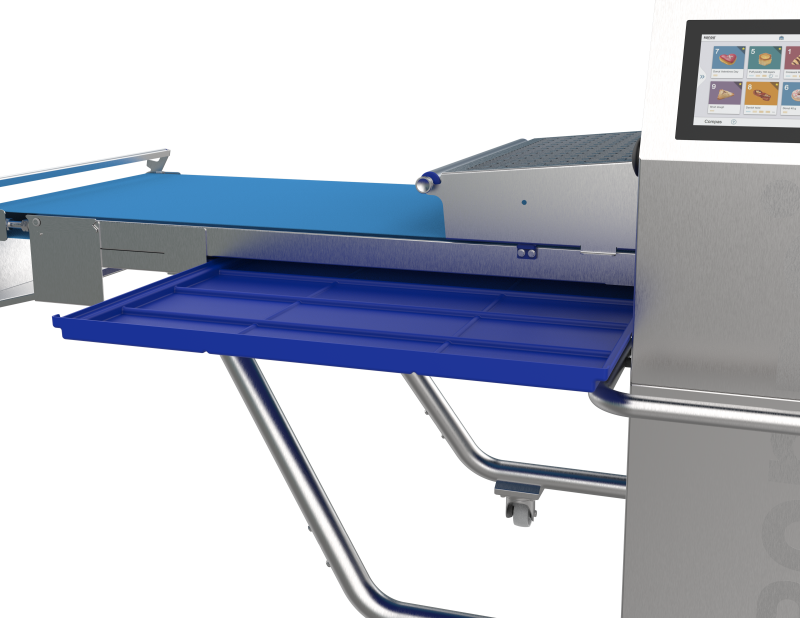

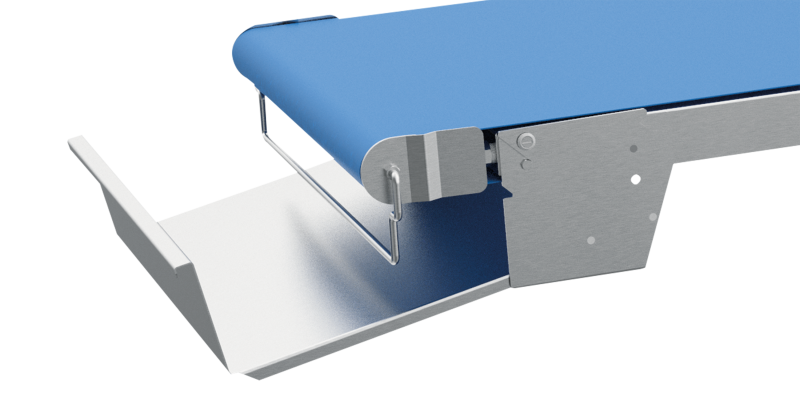

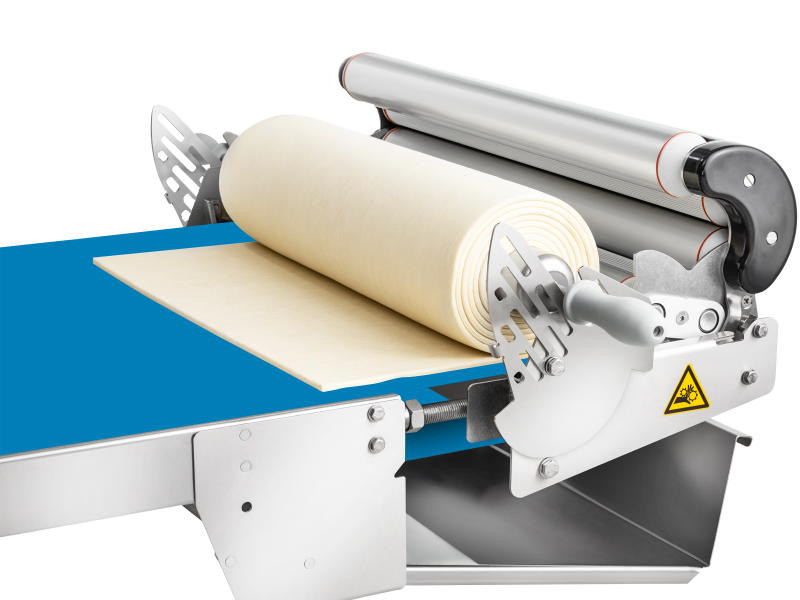

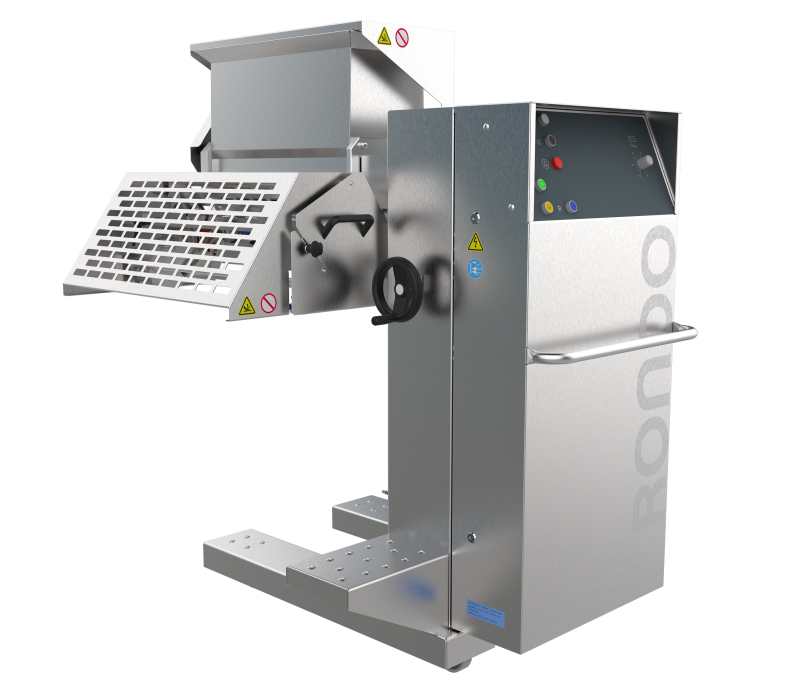

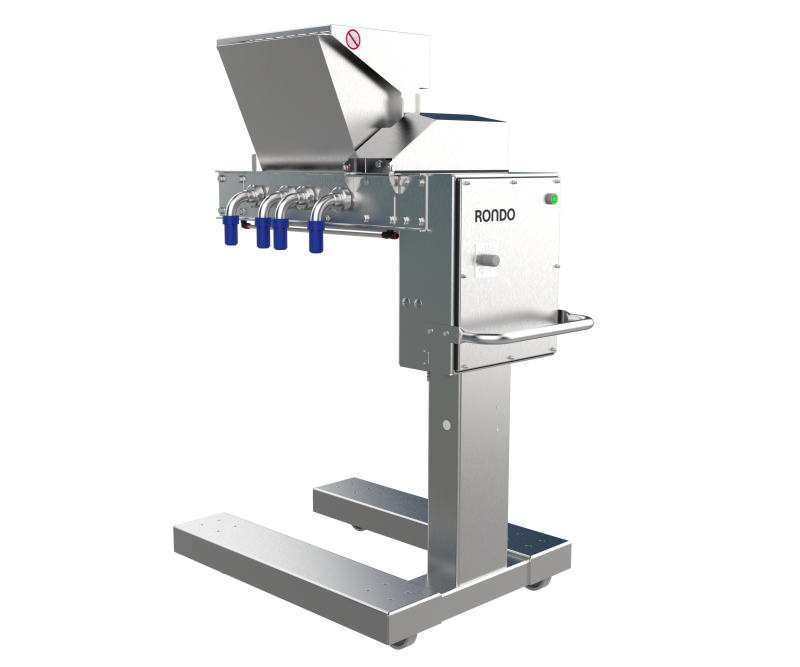

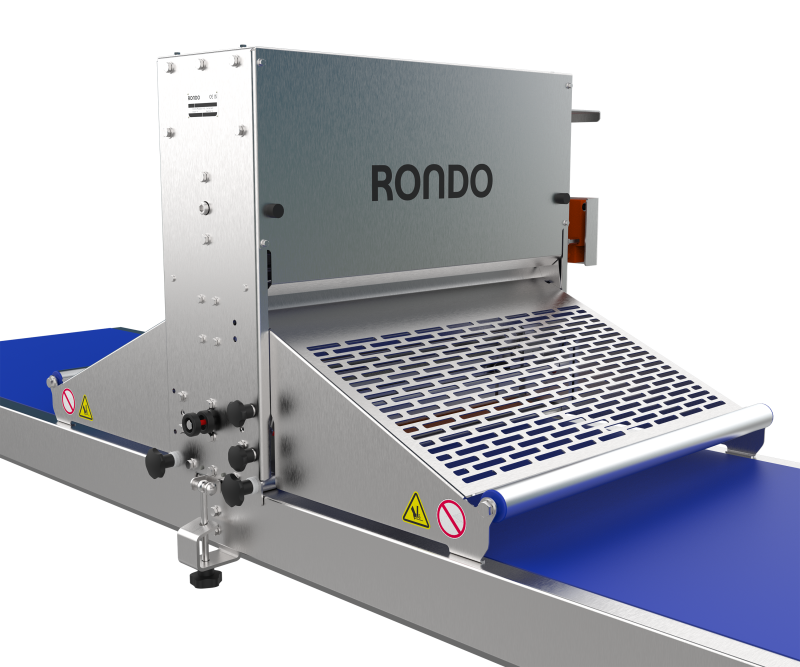

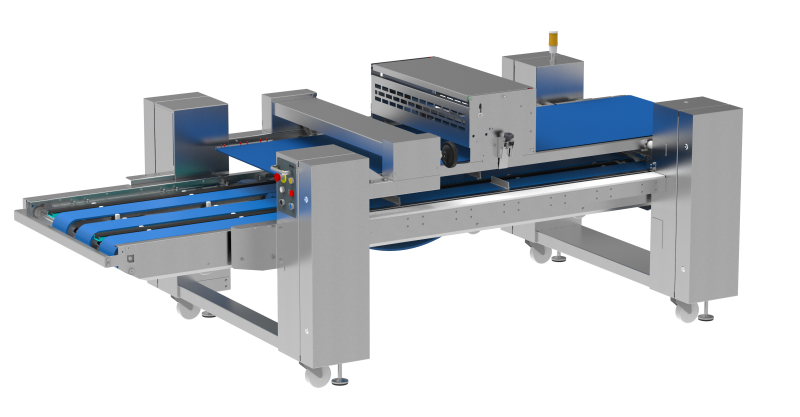

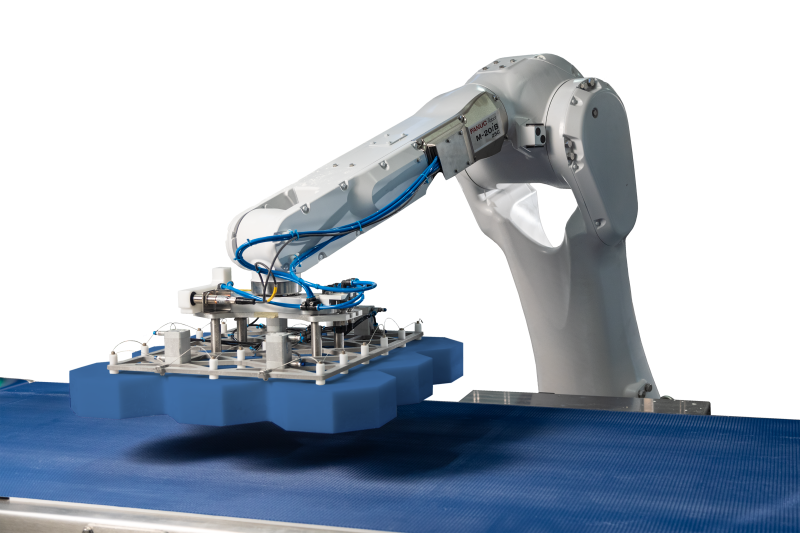

RONDO accessories

Thanks to original accessories from RONDO, you can customise the capacity and degree of automation of your baked goods production line to meet your requirements perfectly. You can find an overview of components, and accessories here.